STACBOND composite panels

Innovation in every layer

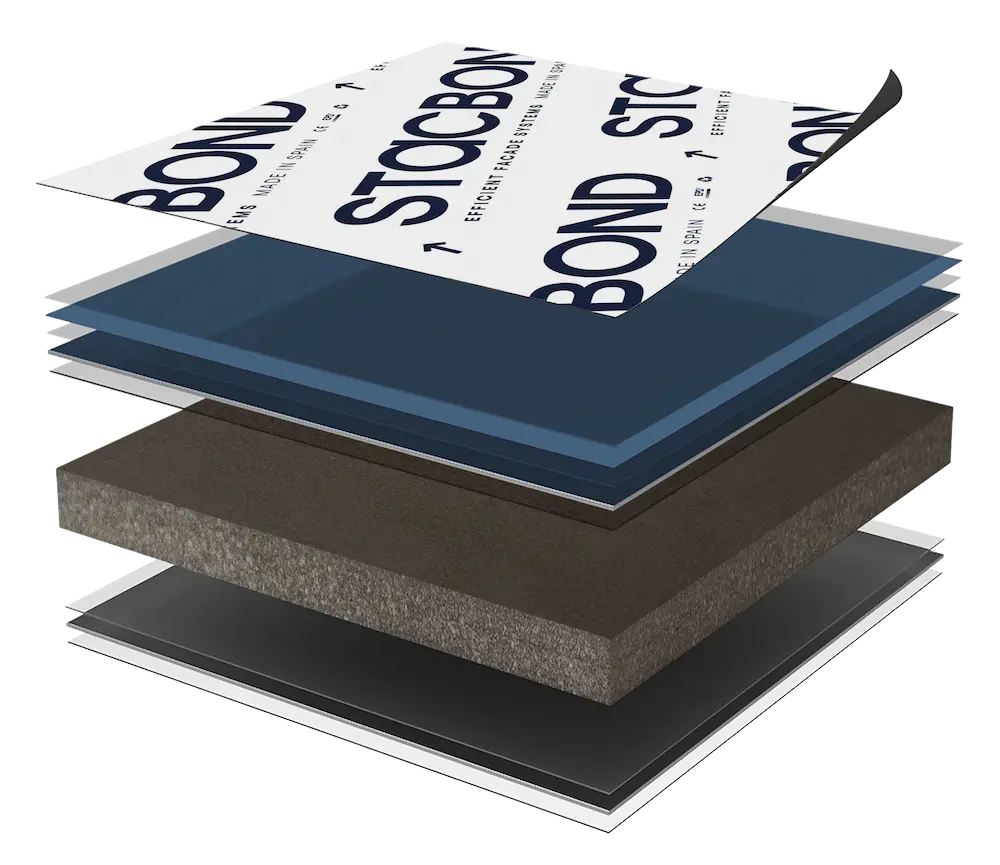

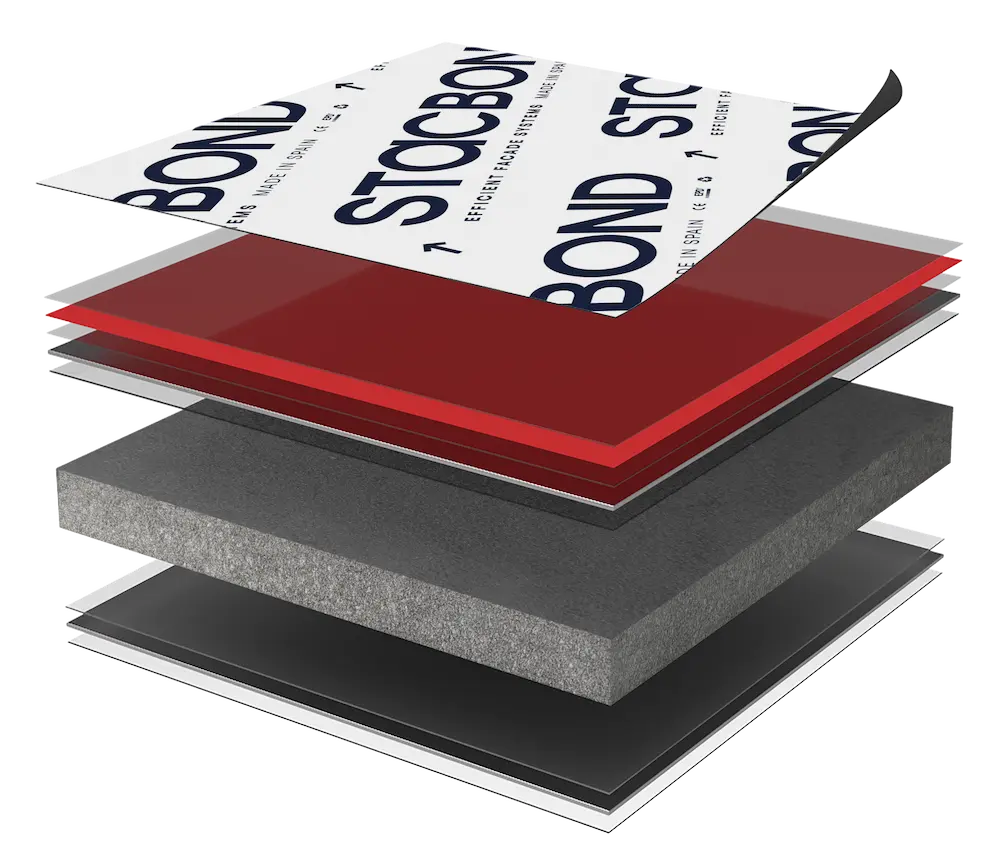

The STACBOND composite panel is an innovative material composed of two 0.5 mm (0.020 in) thick aluminium sheets with a mineral load core that can be either STACBOND A2 or fire retardant STACBOND FR and is coated with special weather-resistant paints.

Advantages of our

Aluminium composite panels

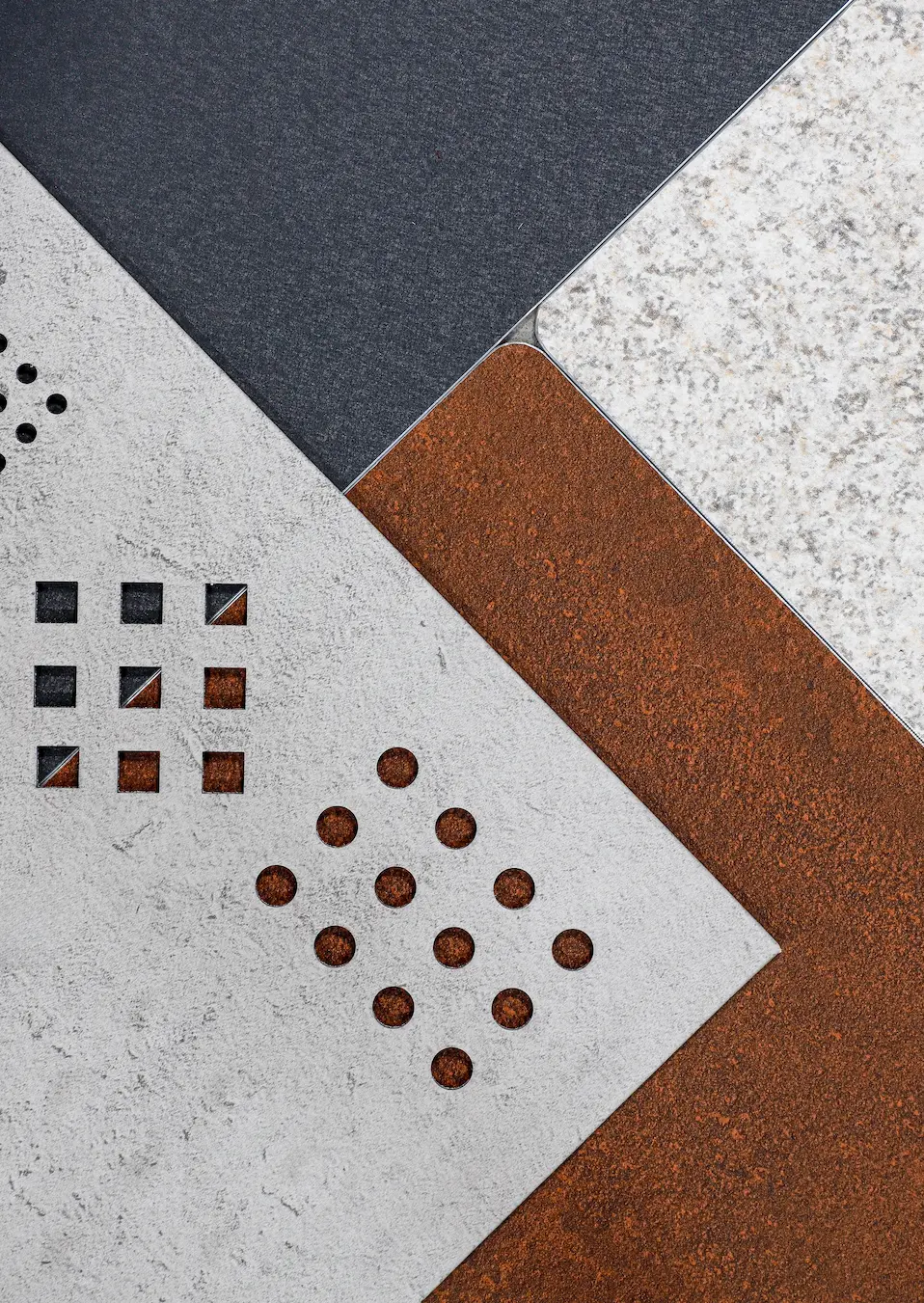

Innovative finishes never before seen in a composite panel

Beyond aluminium

We manufacture composite panel from coils of other metals such as copper and zinc, in various thicknesses (both sheet and core), offering a wide range of solutions to respond to any creative need.

Broadening horizons

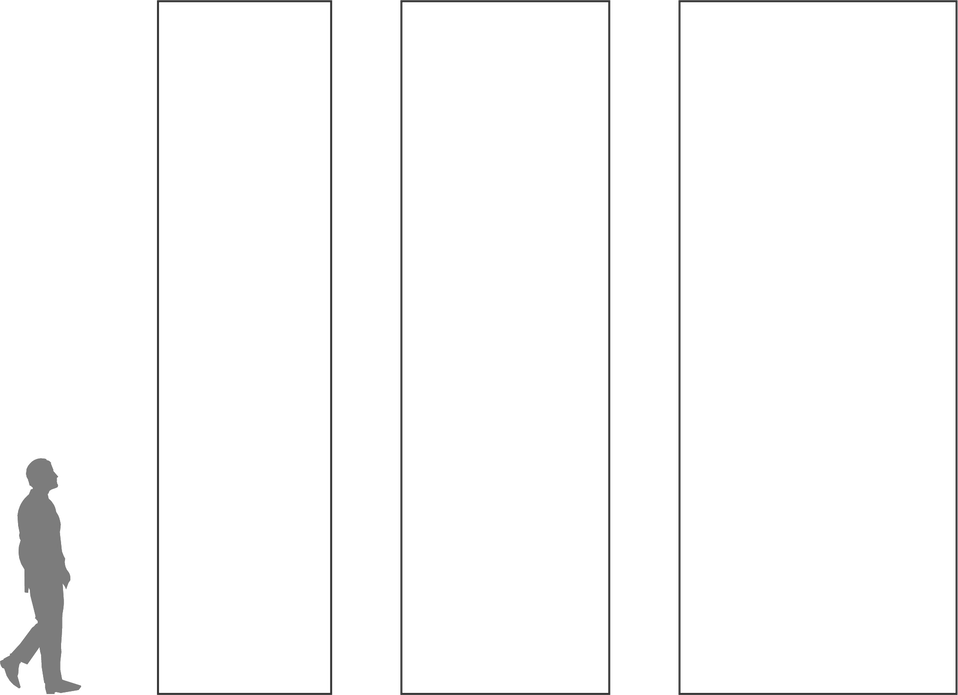

Large panels for your project

STACBOND composite panels are available in 3 standard dimensions of width 1250mm (49.21 in), 1500mm (59.06 in) and 2000mm (78.74 in) and a standard length of 5000mm (196.85 in). We supply other dimensions on request, reaching lengths of more than 14 metres (45.93 ft).

Revolutionary installation, total efficiency.

STACBOND stands out as the leading manufacturer of assembly systems. Our innovative T-CH-PRO and T-SZ-PRO systems enable façade configurations with any length of cassette in both vertical and horizontal layouts.

These new solutions not only allow architects to design more elegant and modern façades, but also contribute to the reduction of costs in the substructure and in installation times, in addition, being removable and reusable systems, they facilitate changing or replacing cassettes which makes them much more efficient.

Transforming ideas into reality

STACBOND panels are easily machined allowing architects and designers to create visually attractive and personalised ventilated façades.

We provide our customers with all panel machining and transformation processes, such as machining, stamping, punching and die cutting, edging of edges, curving by roller and forming.

Recycling and Energy Efficiency

for a Sustainable Future

At STACBOND, our commitment to sustainability is manifested in concrete actions. We give a new life to the aluminium composite panel, promoting a circular economy through recycling, separation and reuse of their components. This not only makes the STACBOND panel an eco-friendly option, but also actively contributes to sustainable construction goals.

We support our practices with environmental product declarations and zero waste certificates. Through our STACBOND Recycling service, we offer our customers a collection system of scraps on site, which are subsequently recycled, thus reducing the associated carbon footprint.

In addition, we collaborate in improving the energy efficiency of the building stock. Most of the aluminium composite panels we produce are intended for ventilated façades, an exterior enclosure construction solution that reduces the energy demand of the building by more than 30%.

In this sense, numerous constructions that incorporate STACBOND composite panels have already obtained LEED and BREEAM certifications, reaffirming their commitment to sustainability and the preservation of the environment.

Certified

quality

STACBOND processes are subject to rigorous tests and quality controls, both internal in our laboratories and external through audits carried out by the most prestigious construction institutes in the various countries where we are certified.