More than façades: efficiency, security and sustainability

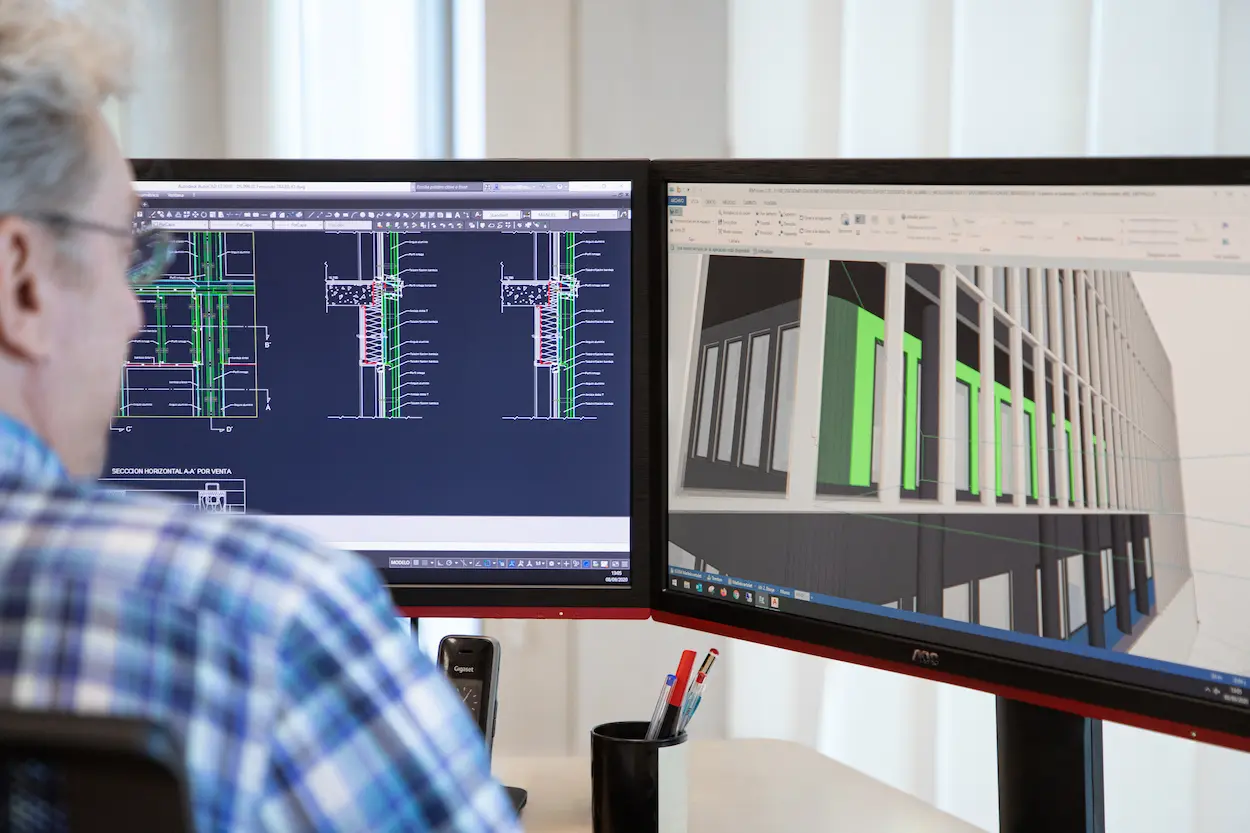

We are specialists in the manufacture of aluminium composite panel and development of assembly systems. In addition, we offer coil painting services for architecture, corporate image, signage, as well as industrial and transport sectors.

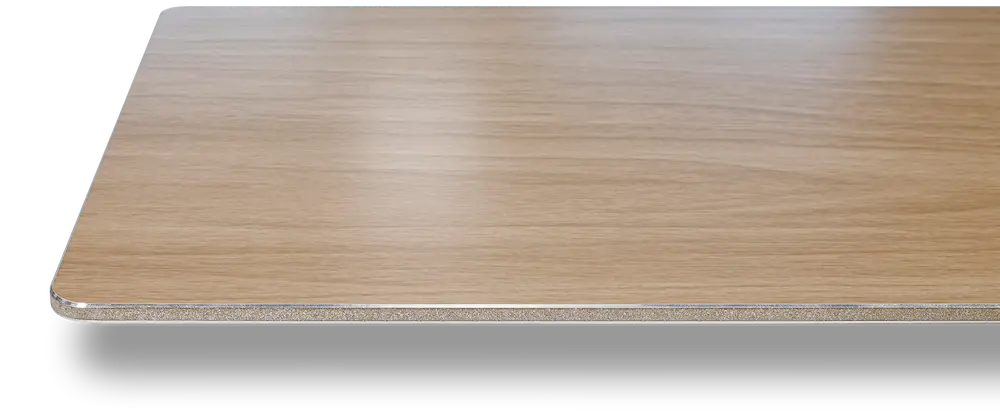

Finishes

that inspire

More than one hundred finishes with different textures and shine that blend with both nature and the most cosmopolitan skylines.

At STACBOND we offer the solution to any design in wood, stone, metal, corten, cement, porcelain finishes, anodised and special colours.

We paint aluminium coil in RAL, Pantone or NCS finishes. If we do not have the finish you are looking for for your project, we can make a countertype from a physical sample.

Featured colours

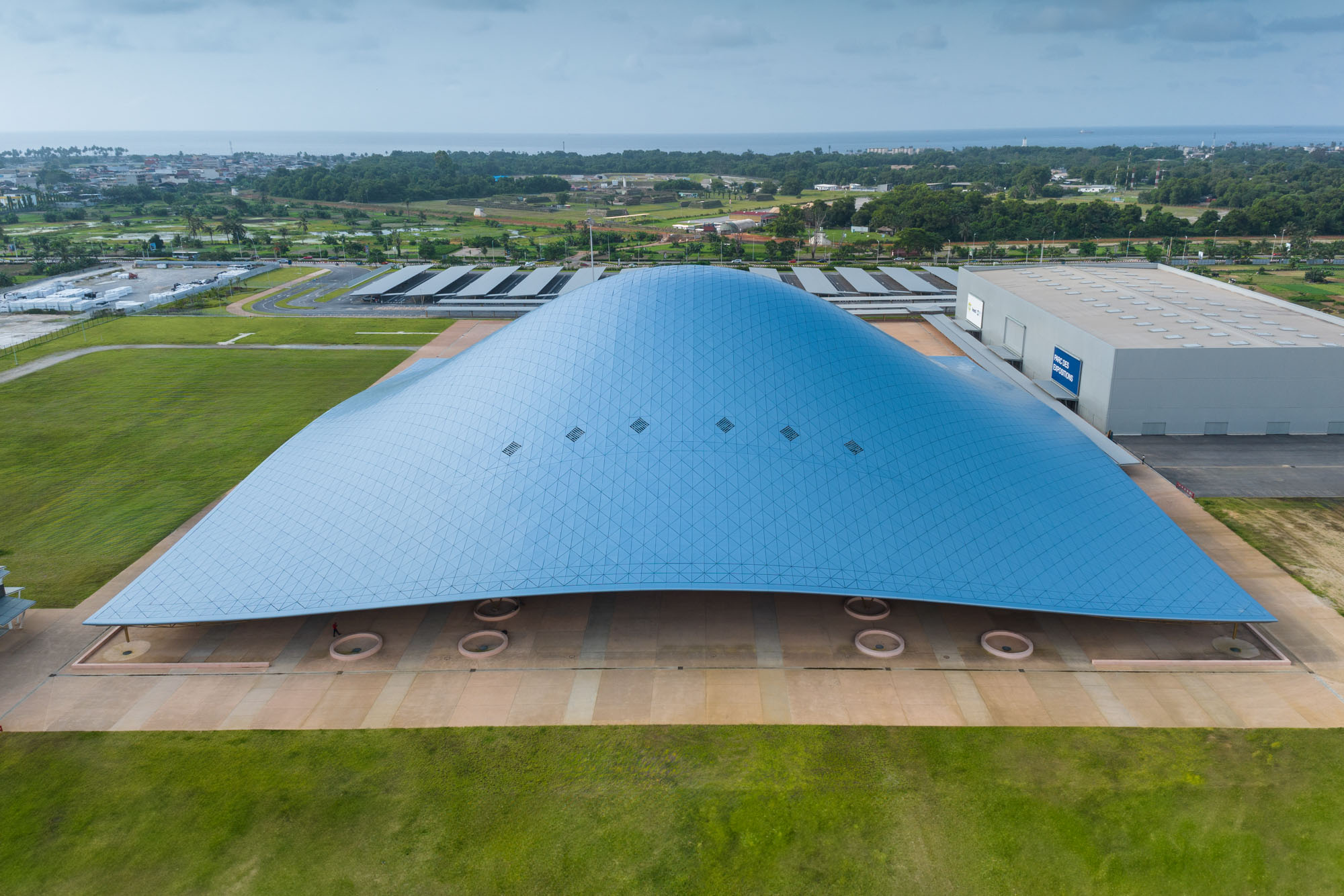

Composite panels for

new construction and renovation

You can find STACBOND aluminium composite panels on façades all over the world in residential buildings; offices; public, health, education and technology centres; hotels and catering; infrastructure; sports and leisure centres; shopping centres and other commercial establishments; industrialisation projects; corporate identity and other uses.

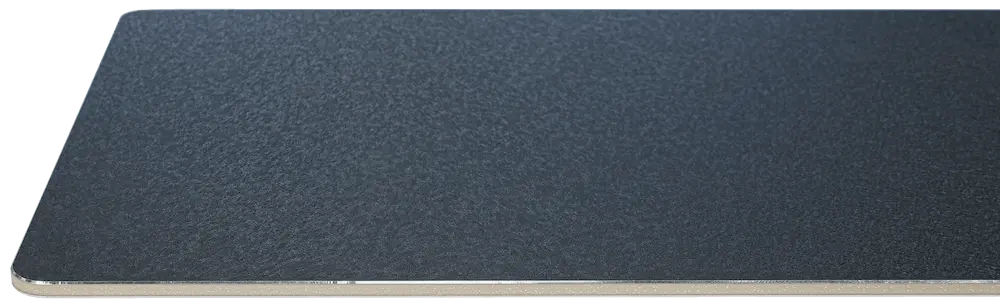

Fire-safe

panels

The STACBOND panel is a material composed of two aluminium sheets and a non-combustible A2 mineral inner core, or FR fire retardant. Their use in ventilated facades together with non-flammable mineral insulation, are a fire-safe solution.

Both the A2 and FR panels also have excellent mechanical properties to highlight: High rigidity, excellent flatness, impact resistance, durability and ease of maintenance.

Quality

certified

STACBOND processes are subject to rigorous testing and quality control, both internally in our laboratories and externally through audits carried out by the most prestigious construction institutes in the different countries where we are certified.